Manufacturing remains a cornerstone of Singapore’s economy. It contributes around 21% of Singapore’s GDP, highlighting its importance. In terms of automation, robot density in the sector is ranked #2 globally, with 605 robots per 10,000 workers. This advanced robotic uptake demonstrates how Industry 4.0 Singapore is central to modern manufacturing here. Manufacturers are using AI and robotics to boost productivity, cut downtime, reduce maintenance costs, and improve resource efficiency.

Building a Sustainable Future

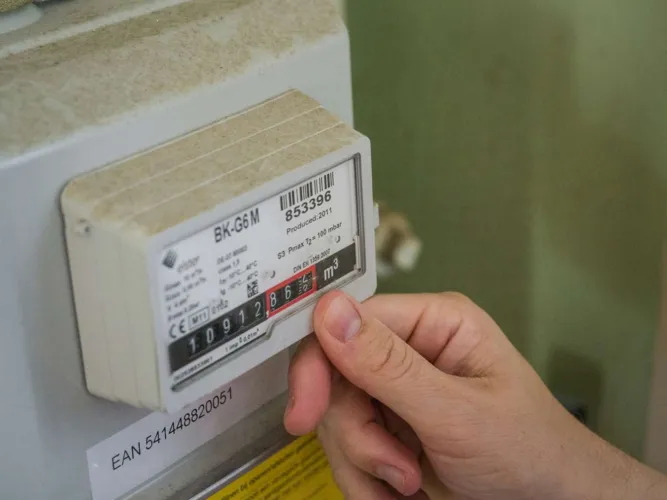

Under the “Manufacturing 2030” vision, Singapore aims to expand the manufacturing sector by 50% by 2030, while reducing carbon intensity. With industry accounting for 46% of national emissions, sustainability is a critical goal.

As part of its Green Plan 2030, the nation aims to cut carbon emission intensity by 36% from 2005 levels. Policies now offer grants and incentives to both multinationals and SMEs investing in green and energy‑efficient technologies.

Policy Tools Driving Change in Industry 4.0 Singapore

Singapore launched the Smart Industry Readiness Index (SIRI)—the world’s first digital maturity model for manufacturers. It guides firms to adopt sustainable tech and digitize operations.

SIRI has become a benchmark used globally to map automation readiness and sustainability goals, firmly embedding Industry 4.0 Singapore into national policy frameworks.

Industry 4.0 Singapore Tech Adoption: AI, Robotics, and Digital Skills

Automation continues to accelerate: industrial robot deployment is rising at 27% per year since 2015, with 730 machines per 10,000 workers on average. This far exceeds global norms.

Talent development is key. Under the SkillsFuture initiative, 520,000 Singaporeans completed digital training by 2023. Yet the country still projects a need for 1.2 million digitally skilled workers by 2025 to support its tech‑driven ambitions.

Read Also: Singapore Advanced Manufacturing Surges with AI Power

Sectoral Strengths: Pharma, Electronics & Precision Tools

Singapore is now the world’s 5th largest exporter of high-tech goods. It hosts operations from major global electronics firms and biotech companies like Micron, GlobalFoundries, and leading pharmaceutical companies.

In pharmaceuticals, four of the world’s top five firms produce high‑value biologics here; four of the top ten global drugs are also manufactured in Singapore.

Precision engineering is another strength: over 3,000 companies operate in this space. With 15,000+ STEM graduates annually, Singapore maintains a deep talent pipeline for advanced manufacturing.

Read Also: Across Industries: Singapore AI Integration Strategy & Playbook

R&D, Innovation, and Public‑Private Partnerships

New S$500 million state‑of‑the‑art R&D hubs for semiconductors and life sciences encourage innovation and industry‑university collaboration.

Government initiatives such as the Pioneer Certificate Incentive, Development & Expansion Incentive, and PACT programme support foreign firms and SMEs in upgrading production lines, co‑innovation, and exporting. These schemes underscore a supportive ecosystem for Industry 4.0 Singapore.

Industry 4.0 Singapore: Investors Back the Vision

After a slower 2024, manufacturing growth is expected to rebound strongly through 2028. Advanced clusters like semiconductors and precision tools are already seeing high demand and near‑full production. With robust policy support, automation readiness, and skilled workers, Industry 4.0 Singapore offers a fertile environment for global investment in high‑value, sustainable manufacturing.

FAQs

Q: What is Industry 4.0 Singapore?

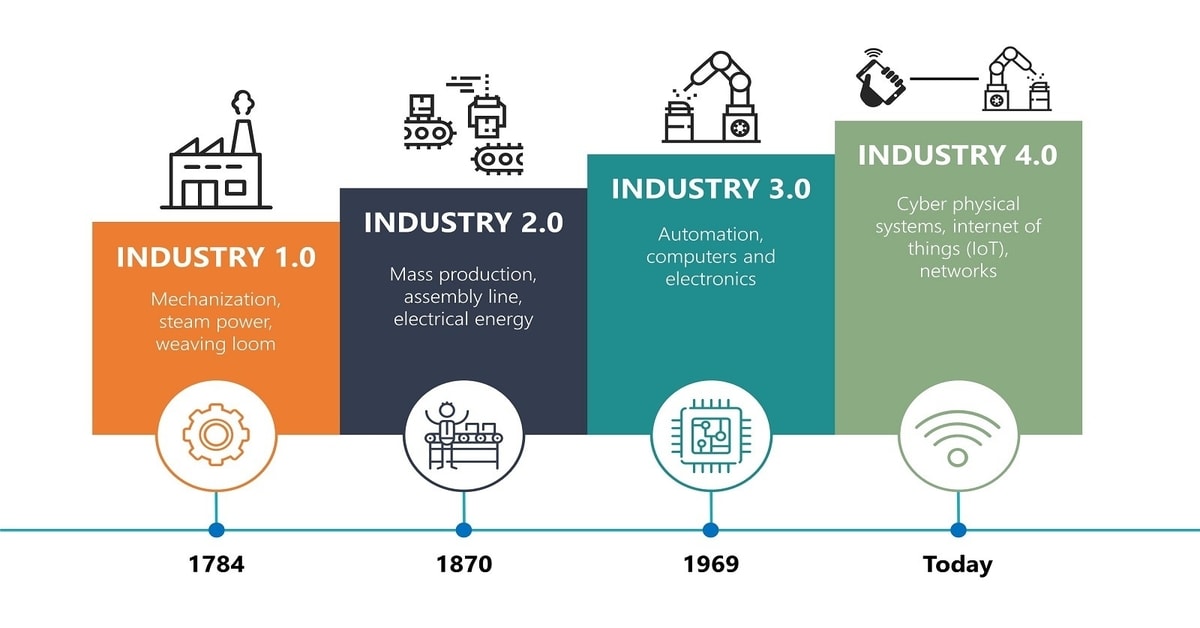

A: It refers to Singapore’s national push to integrate automation, AI, and digitization into its manufacturing sector.

Q: How is Singapore reducing emissions in factories?

A: Through policies under Green Plan 2030, including tools like the Smart Industry Readiness Index and green technology incentives.

Q: Which industries are key for this shift?

A: Pharmaceuticals, electronics, semiconductors, and precision engineering are at the forefront of Industry 4.0 adoption.

Q: What role do skills and training play?

A: Digital upskilling through SkillsFuture is essential—about 520,000 people trained so far, with more needed to meet industry demands.